The Difference: HydraStone™ Cement Lining

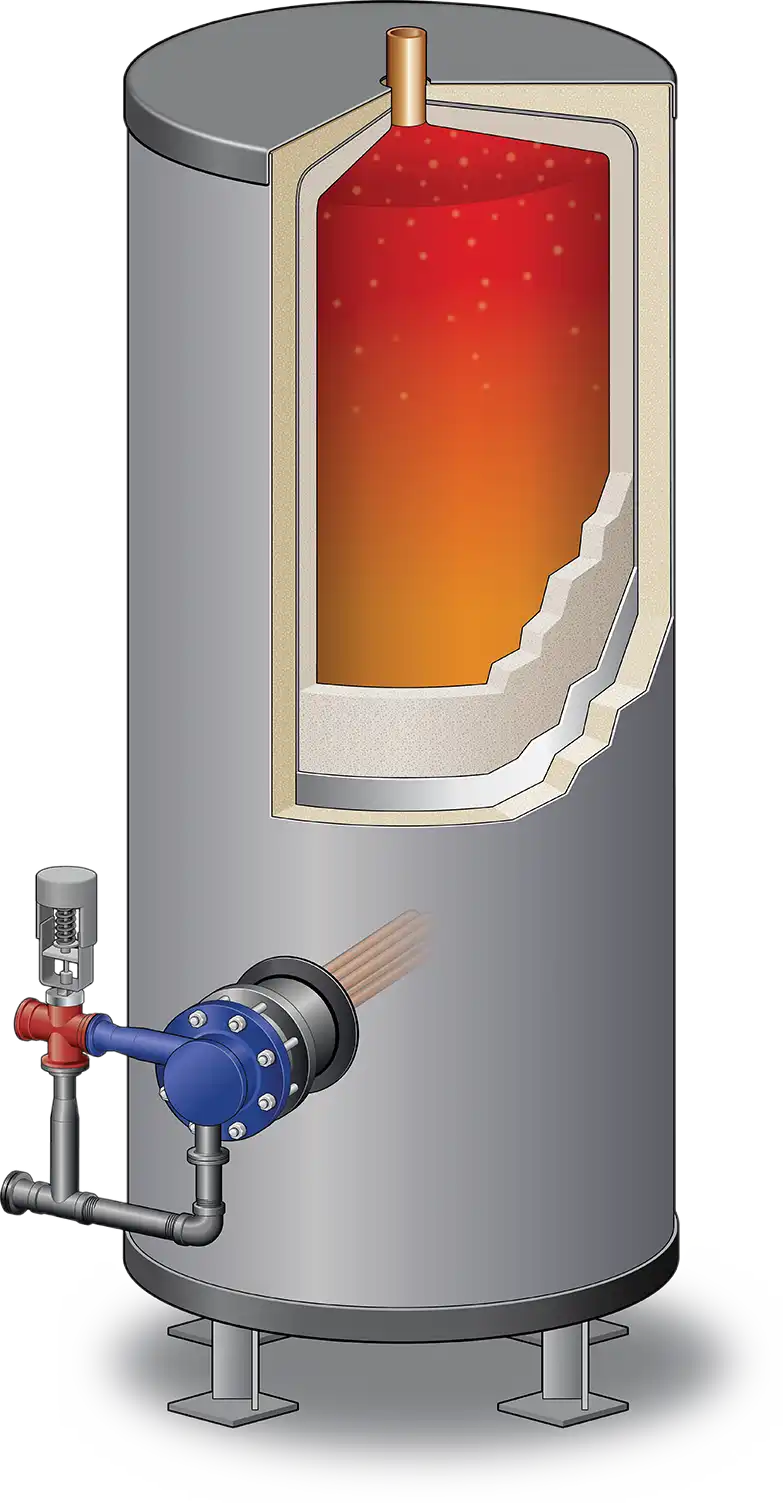

Cement lined tanks offer significant longevity, trouble-free operation and a lower lifetime cost.

The tank's protective lining is the deciding factor for water heater quality. Hubbell Heaters HydraStone cement lining provides complete, reliable coverage.

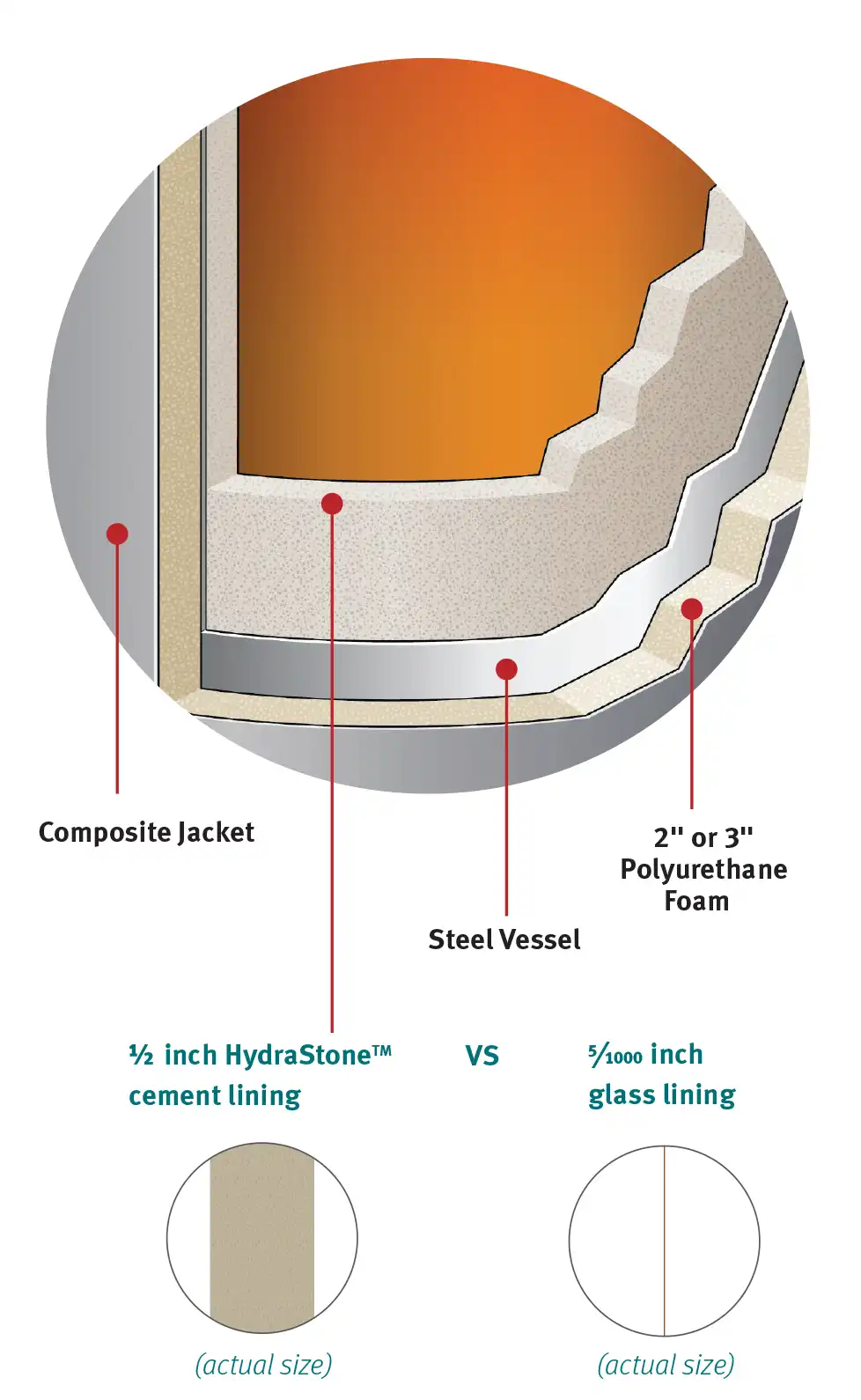

The lining's ability to protect the steel tank depends primarily on its thickness and full surface coverage. A glass lined tank uses only 5/1000 inches of glass (the thickness of a sheet of paper) and does not cover all internal surfaces. To compensate, all glass lined tanks require a sacrificial anode rod, which must be inspected and replaced regularly.

Our tanks are lined with a minimum of ½ inch of high density HydraStone cement — 100 times thicker than glass lining. We achieve full tank coverage by injecting HydraStone cement into each tank and centrifugally spinning it at 250 RPM. This process provides maximum protection from the corrosive effects of hot water. Since cement lined tanks do not require a sacrificial anode, this eliminates the periodic inspections and replacement costs associated with glass lined tanks. Our water heater tanks are constructed with solid non-ferrous copper-silicon tank tappings, impervious to the corrosive effects of hot water. Glass-lined tanks have steel tappings, vulnerable to corrosion.