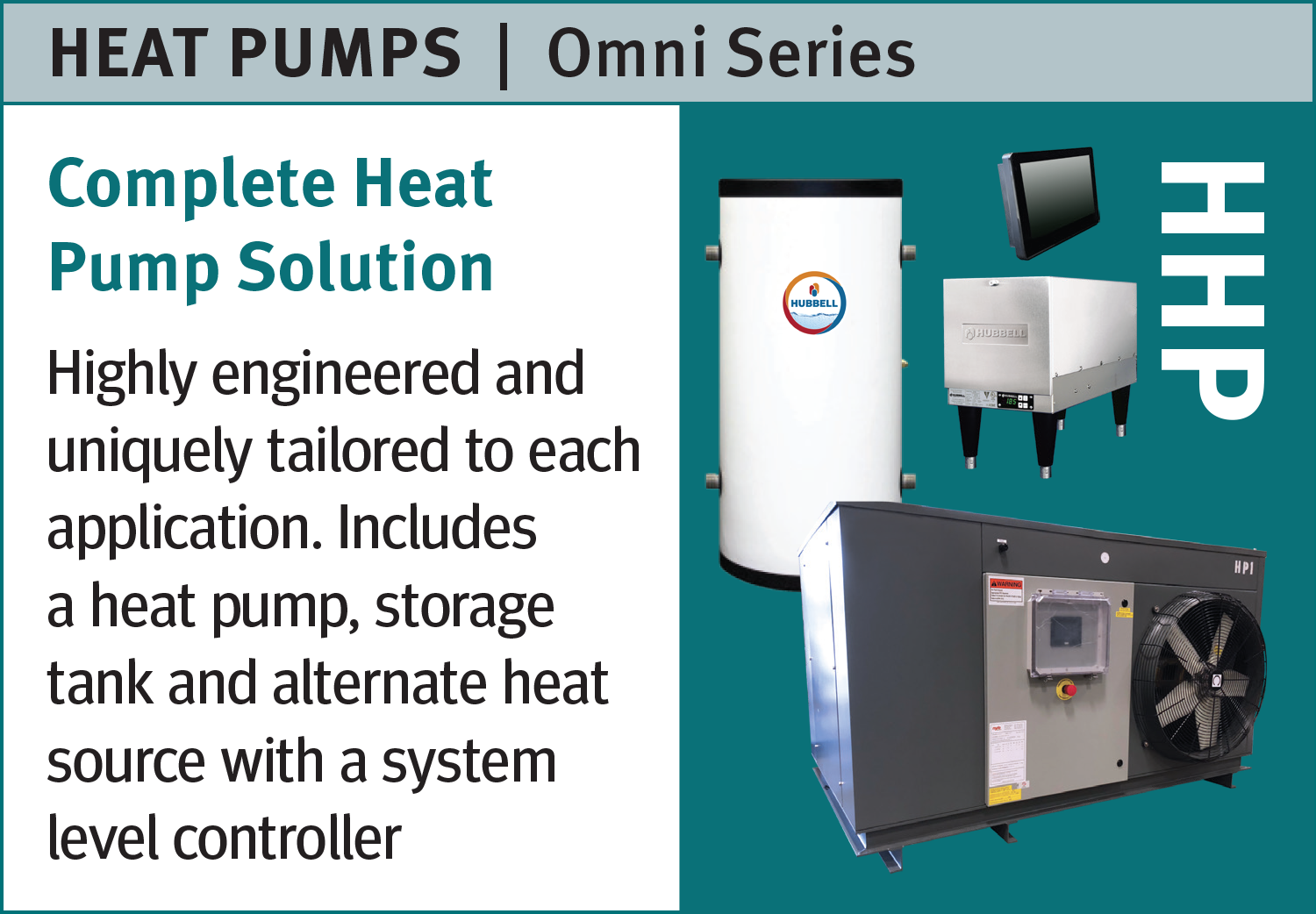

Omni Series

PBX

Electric Heat Pump Water Heater

A fully integrated, economical, energy efficient heat pump water heater. Available in 50, 65, 80, and 119 gallon capacities.

HYDRASTONE CEMENT LINING

INCOLOY SHEATH BACKUP HEATERS

INDUSTRY LEADING EFFICIENCY

PROVEN HEAT PUMP TECHNOLOGY

SIMPLE INSTALLATION

Applications

Residential buildings, restaurants, schools, office buildings, and much more.

Omni Series

PBX

Electric Heat Pump Water Heater

A fully integrated, economical, energy efficient heat pump water heater. Available in 50, 65, 80, and 119 gallon capacities.

HYDRASTONE CEMENT LINING

INCOLOY SHEATH BACKUP HEATERS

INDUSTRY LEADING EFFICIENCY

PROVEN HEAT PUMP TECHNOLOGY

SIMPLE INSTALLATION

Applications

Residential buildings, restaurants, schools, office buildings, and much more.

PBX Overview

Technical Documents

Request Info about the PBX

You might also be interested in ...

Hubbell has a water heater for almost every application. Take a look at other options.