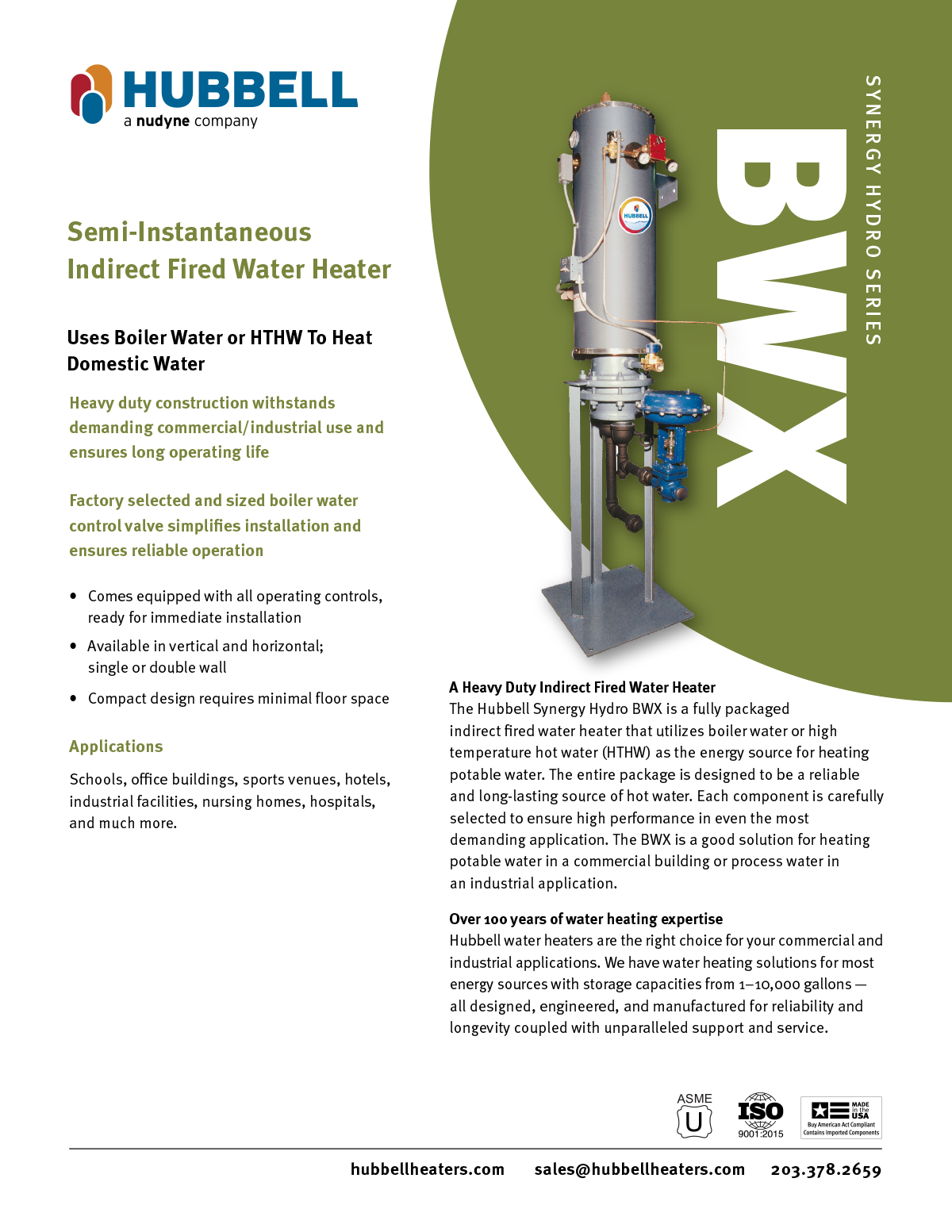

Synergy Hydro Series

BWX

Semi-Instantaneous Indirect Fired Water Heater

Uses Boiler Water or HTHW to Heat Domestic Water

CONTINUOUS HOT WATER SYSTEM

SMALL FOOTPRINT

WIDELY CUSTOMIZABLE

SIMPLE INSTALLATION

Applications

Schools, office buildings, sports venues, hotels, industrial facilities, nursing homes, hospitals heat recovery systems, and much more.

Synergy Hydro Series

BWX

Semi-Instantaneous Indirect Fired Water Heater

Uses Boiler Water or HTHW to Heat Domestic Water

CONTINUOUS HOT WATER SYSTEM

SMALL FOOTPRINT

WIDELY CUSTOMIZABLE

SIMPLE INSTALLATION

Applications

Schools, office buildings, sports venues, hotels, industrial facilities, nursing homes, hospitals heat recovery systems, and much more.

BWX Overview

Technical Documents

Request Info about the BWX

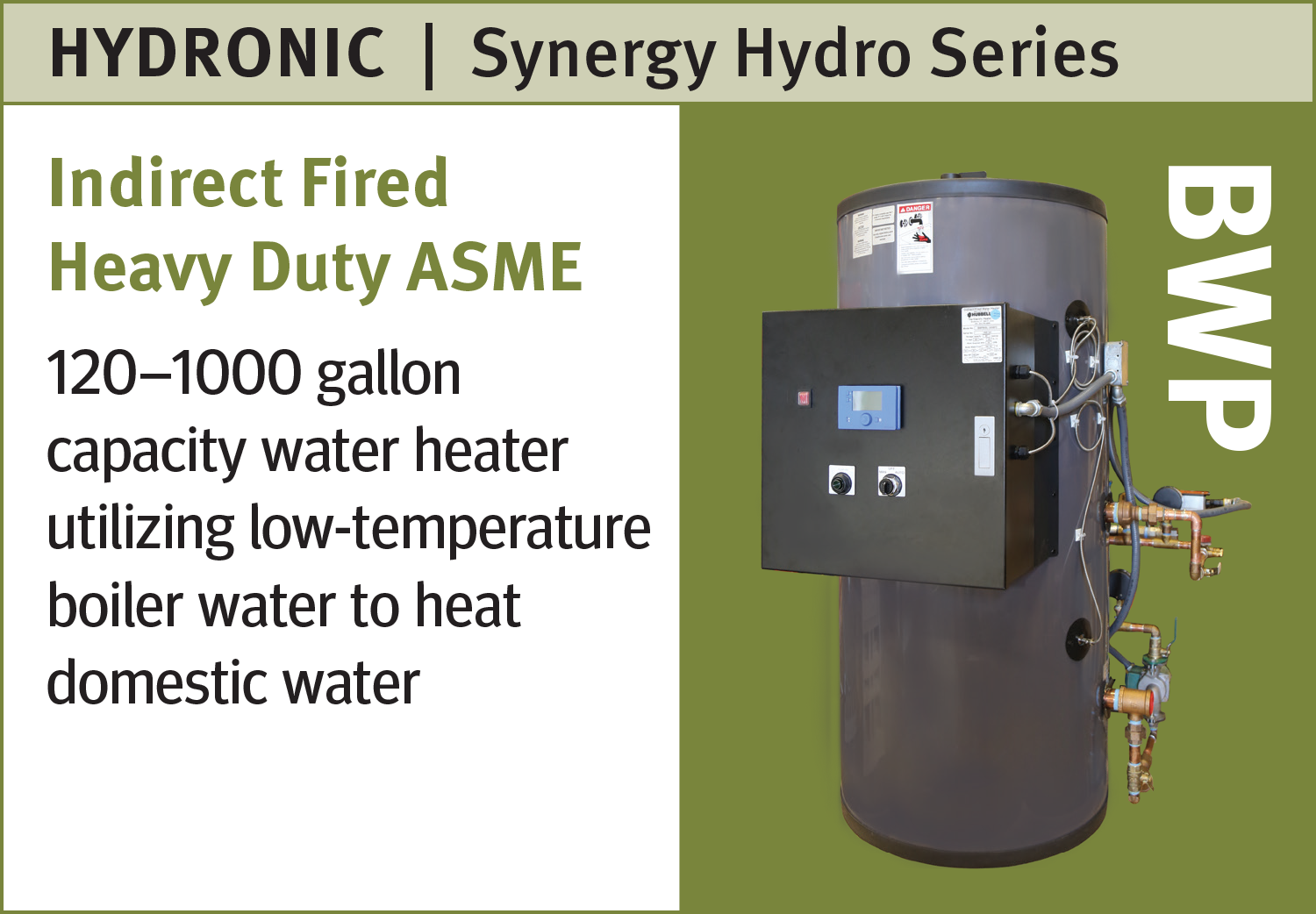

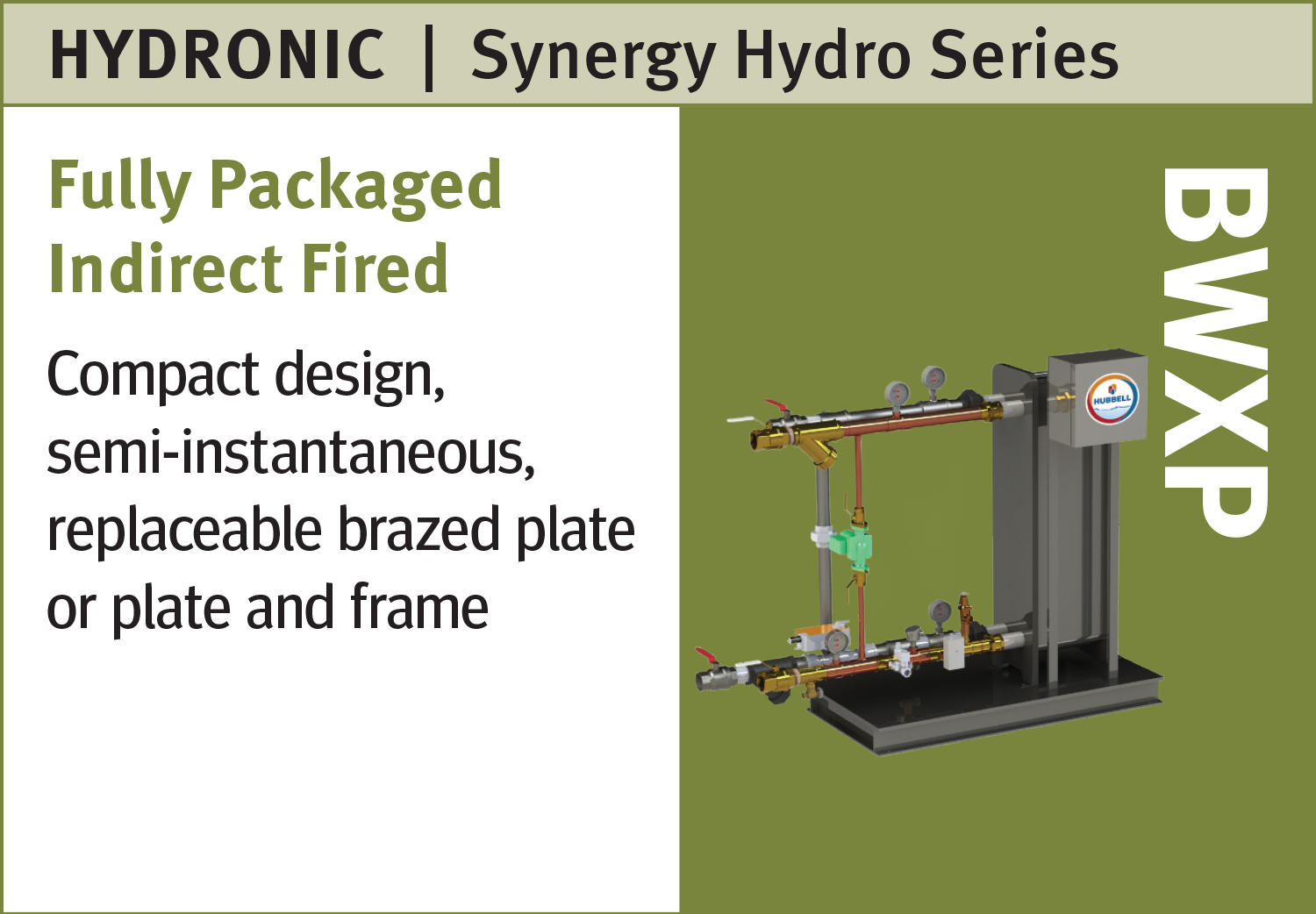

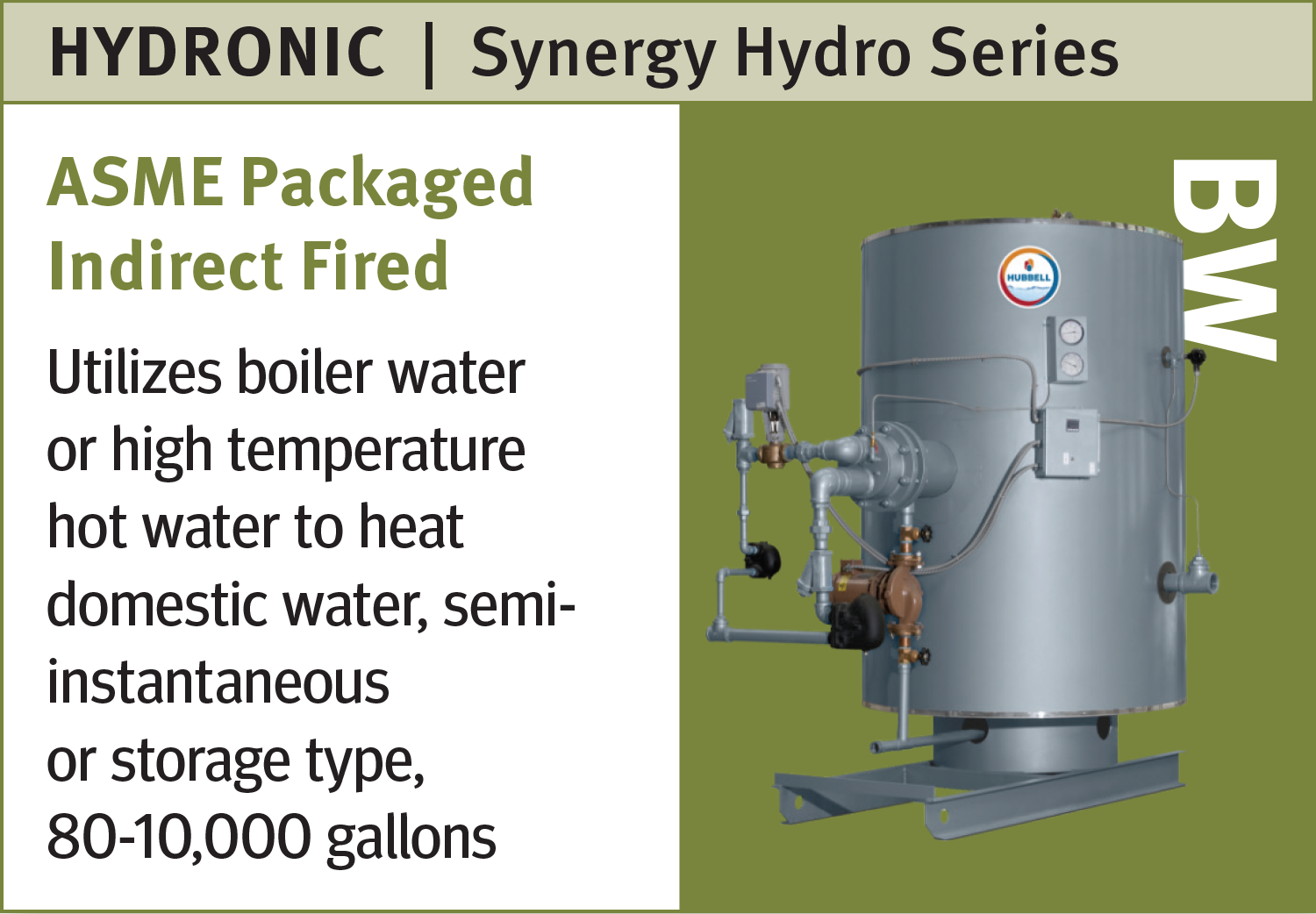

You might also be interested in ...

Hubbell has a water heater for almost every application. Take a look at other options.