Synergy Steam Series

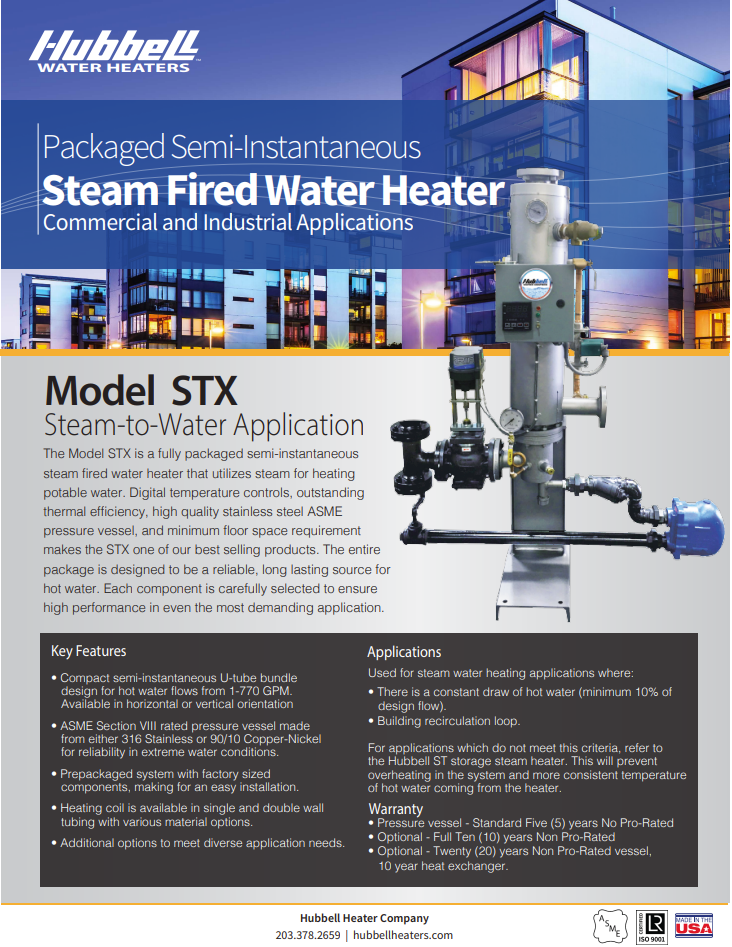

STX

Packaged ASME Semi-Instantaneous Steam Fired Water Heater

Fully packaged system, provides up to 10,500 GPH

ASME STAMPED

FULLY PACKAGED SYSTEM

WIDELY CUSTOMIZABLE

HIGH GRADE MATERIALS

NON-FERROUS PRESSURE VESSEL

Applications

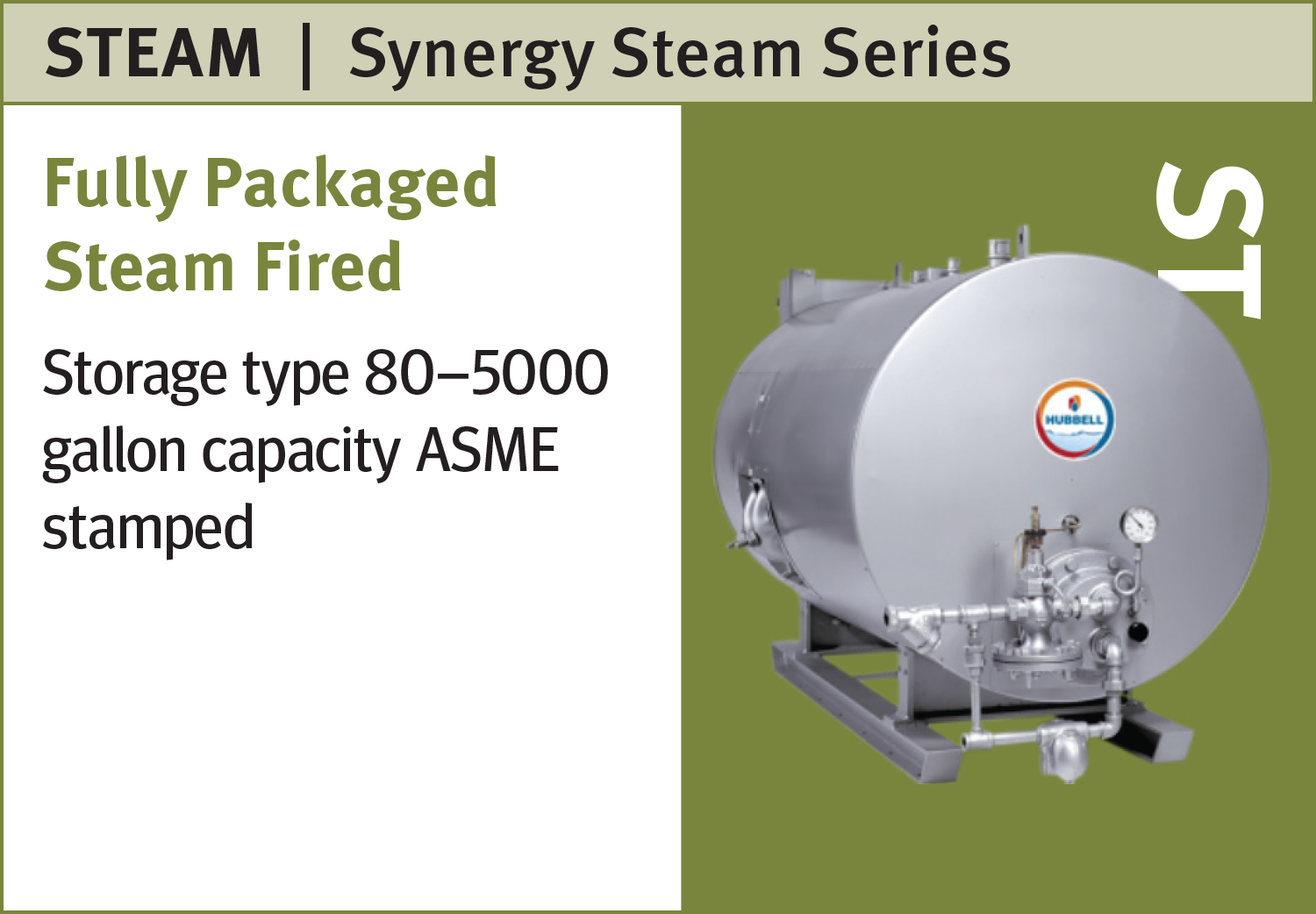

Used for steam water heating applications where: • There is a constant draw of hot water (minimum 10% of design flow) • Building recirculation loop For applications which do not meet this criteria, refer to the Hubbell ST storage steam heater. This will prevent overheating in the system and more consistent temperature of hot water coming from the heater.

Synergy Steam Series

STX

Packaged ASME Semi-Instantaneous Steam Fired Water Heater

Fully packaged system, provides up to 10,500 GPH

ASME STAMPED

FULLY PACKAGED SYSTEM

WIDELY CUSTOMIZABLE

HIGH GRADE MATERIALS

NON-FERROUS PRESSURE VESSEL

Applications

Used for steam water heating applications where: • There is a constant draw of hot water (minimum 10% of design flow) • Building recirculation loop For applications which do not meet this criteria, refer to the Hubbell ST storage steam heater. This will prevent overheating in the system and more consistent temperature of hot water coming from the heater.

STX Overview

Technical Documents

Request Info about the STX

You might also be interested in ...

Hubbell has a water heater for almost every application. Take a look at other options.